The Ultimate Guide to Ruby Wire Manufacturing

In the world of commercial reducing innovation, diamond cable manufacturing has emerged as a game-changer. It's not just a particular niche item any longer; it's a critical tool throughout various industries, from semiconductor fabrication to rock cutting. Whether you're a skilled professional or an interested beginner, this overview will certainly walk you with whatever you require to understand concerning diamond wire production. We'll cover the complex procedure, highlight the essential functions of top notch ruby cable, explore its benefits in industrial applications, contrast it to traditional reducing approaches, analyze multi cord systems, and evaluate the latest technologies in diamond cord modern technology.

Comprehending the Process of Ruby Wire Production

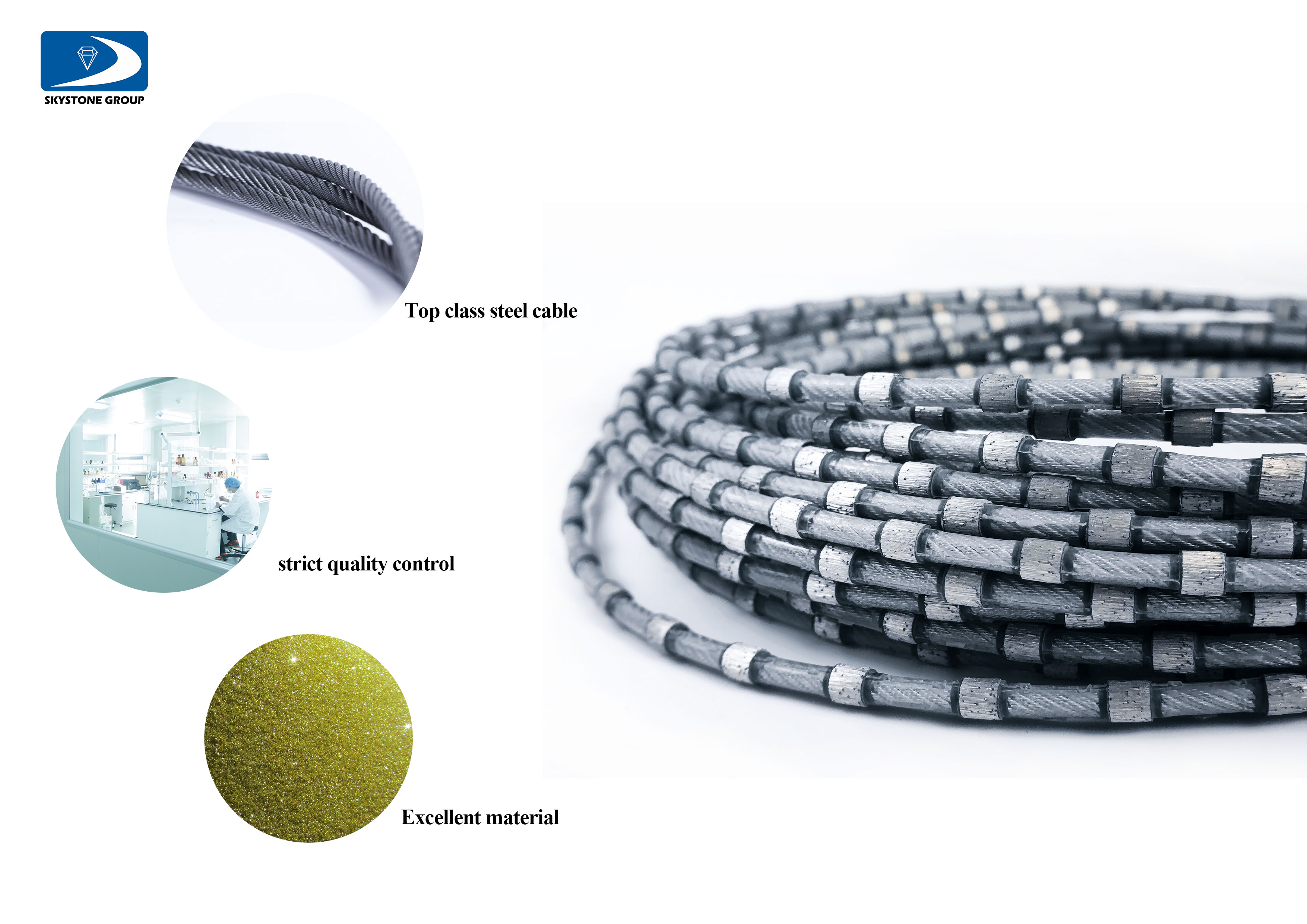

Ruby wire manufacturing is a customized procedure that involves finishing a thin cord, typically made from steel, with diamond bits. The process begins with the option of the core wire, which have to be both strong and flexible to handle the rigors of industrial cutting.Next, the cord is gone through a collection of bathrooms that cleanse and prepare its surface area. Once prepped, the cord undergoes an electroplating procedure where diamond bits are carefully bound to its surface area. This step is crucial for guaranteeing that the diamond covering sticks consistently, providing consistent cutting performance.Finally, the cord is subjected to strenuous high quality checks to ensure it meets sector criteria. These checks usually consist of tensile strength tests, layer thickness dimensions, and reducing performance evaluations. The result is a high-performance diamond cable ready for a variety of industrial applications.

Trick Attributes of High-Quality Diamond Cord

When it comes to ruby cable, not all items are produced equal. Top quality ruby wire flaunts several key attributes that set it apart from minimal alternatives.Firstly, the harmony of the diamond coating is critical. Inconsistent finish can cause irregular cutting, which can endanger the accuracy needed in numerous industrial tasks. A top notch diamond cable will have a consistent finishing that guarantees every part of the wire performs consistently.Secondly, the tensile toughness of the core wire is vital. A high-strength core cable can hold up against the stress and anxieties of high-speed cutting, minimizing the danger of breakage and downtime. This is especially vital for applications that need continual operation.Lastly, premium ruby wire will have exceptional cutting effectiveness. This indicates it can cut via materials much faster and with less effort, bring about increased efficiency and decreased functional prices. Efficiency is commonly determined by the rate and level of smoothness of the cut, along with the longevity of the cable itself.

Benefits of Using Diamond Wire in Industrial Applications

The advantages of making use of ruby cable in industrial applications are countless and impactful. One of the most significant advantages is its capacity to create exact cuts. The diamond-coated surface permits extremely great and exact cutting, which is important in industries such as semiconductor production and gemstone cutting.Another major advantage is the decrease in product waste. Standard reducing approaches frequently lead to considerable material loss, yet diamond cable cutting is much more effective. This not only saves money yet also makes the process extra eco friendly.Additionally, ruby cord cutting generates less warmth compared to standard methods. This is particularly helpful in applications where warm can damage the material being cut, such as in the fabrication of digital elements. The reduced warmth generation additionally suggests there is much less thermal distortion, resulting in cleaner cuts and much less post-processing job.

Contrasting Diamond Wire to Typical Cutting Approaches

When comparing ruby wire to standard reducing approaches, several elements enter play. Standard approaches like saw blades and unpleasant wheels have been the standard for years, but they feature their very own set of limitations.One of the primary drawbacks of conventional techniques is the quantity of force called for to reduce through tough materials. This commonly causes raised deterioration on the cutting devices, leading to greater upkeep expenses and lowered device life.In contrast, diamond cable reducing calls for dramatically less pressure, many thanks to the solidity of the diamond bits. This minimizes use on the cutting tools and expands the lifespan of the cable. In addition, diamond cord reducing generates smoother sides, lowering the demand for additional completing processes.Traditional methods likewise tend to produce more warm and vibrations, which can compromise the integrity of the material being cut. Diamond cord cutting, on the other hand, produces very little warm and vibrations, making it suitable for fragile and high-precision applications.

diamond wire saw manufacturers in Ruby Cable Technology

The field of diamond cable innovation is consistently progressing, with new developments enhancing its abilities and broadening its applications. One of the most exciting developments is the arrival of multi- wire saw devices. These makers make use of several hairs of diamond cord all at once, drastically enhancing reducing speed and efficiency.Another advancement is using sophisticated coverings that enhance the longevity and cutting performance of diamond cord. These coverings can improve the bond in between the diamond particles and the core cord, expanding the life expectancy of the cable and maintaining its cutting effectiveness over longer periods.Additionally, improvements in cord saw maker production have actually resulted in much more accurate and trustworthy devices. Modern wire saw machines are furnished with sophisticated control systems that permit fine-tuned adjustments, guaranteeing optimum cutting conditions for a wide variety of products.

Ruby cord manufacturing is reinventing the commercial cutting landscape. With its superior accuracy, effectiveness, and resilience, ruby wire is quickly ending up being the best choice for a selection of applications. From customer care to provide chain monitoring, the benefits are clear. By recognizing the procedure, identifying the attributes of high-quality wire, and remaining abreast of technological advancements, companies can utilize this cutting-edge modern technology to attain better success and sustainability.

For those ready to take the following action, exploring the offerings of a reputable ruby cable supplier or cable saw device maker can provide useful understandings and chances. Whether you're aiming to boost your operations or obtain an one-upmanship, the world of diamond cord technology holds enormous potential.